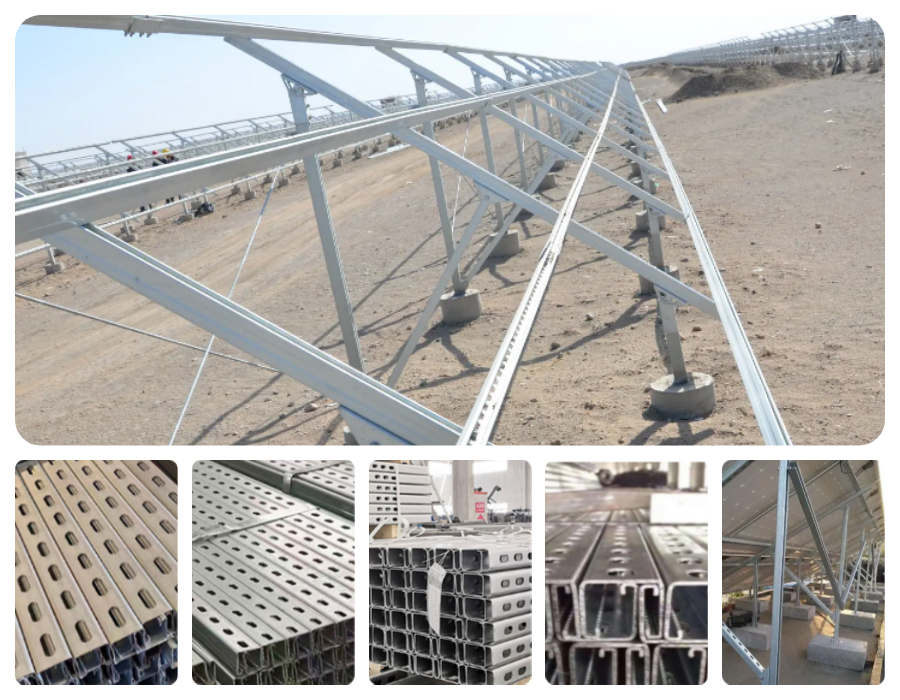

Solar photovoltaic supports are generally made of aluminum alloy or carbon steel, and the surface of carbon steel needs to be hot-dip galvanized. Solar photovoltaic support systems need to be characterized by wind and snow resistance, wind and sand resistance, and corrosion resistance. With the development of many large ground applications, ZAM anti-corrosion iron support photovoltaic products have received many customer inquiries and orders. Today, Kinsend will take you through the ZAM PV support system.

Carbon steel solar supports rely on surface

plating and coating to improve material corrosion resistance. In engineering

projects, it is necessary to consider issues such as welding, drilling,

corrosion protection of cutting edges, and repair of coating scratches. Surface

corrosion resistant coatings can be divided into two types: pre treatment and

post treatment.

Zinc aluminum magnesium (SZAM 150g, 275g)

coatings have better corrosion resistance than GI/700 galvanized sheets in the

current market under severe corrosion conditions. As an alternative to hot-dip

galvanized photovoltaic brackets, they are widely used in areas with

atmospheric corrosion levels of C3, C4, and even C5.

• Cancelling the hot dip galvanizing

production process can reduce the resulting serious environmental pollution

issues, and the products are more in line with the national requirements for

green environmental protection;

• The zinc aluminum magnesium coated plate is

directly provided for engineering use after processing and forming, shortening

the processing period of component products, and achieving good controllability

of the project duration; And reduce the management and labor costs required for

the hot dip post treatment process.

• Zinc aluminum magnesium plated components

have higher corrosion resistance and better coating thickness uniformity.

• Automatic repair, zinc, aluminum, and

magnesium will automatically repair cutting. Magnesium ions and oxygen ions

undergo oxidation-reduction reactions, and the "white rust"

protective layer formed on the stent achieves automatic repair.

• Competitive price advantage, lower price

than aluminum bracket material,

Application of ZAM photovoltaic bracket:

Solar ZAM photovoltaic

brackets can be divided into ground brackets, planar roof brackets, adjustable

angle roof brackets, and customized column brackets. In particular, large-scale

ground support systems are the most widely used, with simple processing,

galvanized aluminum magnesium photovoltaic support, and direct cutting for use.

Kinsend recently received more customer

inquiries regarding ZAM steel solar bracket ordering. Our products have passed the

certification of international testing institutions (including European Union

testing certification, Southeast Asia, South America and other product

certification). Professional photovoltaic bracket manufacturing and design

provide you with the safest project protection. Looking forward to your project

consultation: Mail: Info@kinsend.com ,Web:

www.kinsend.com

Hot Sale Solar Mounting Solutions recommend for you