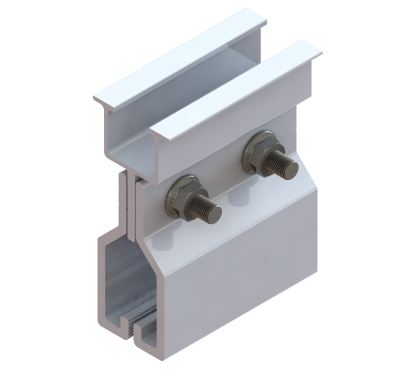

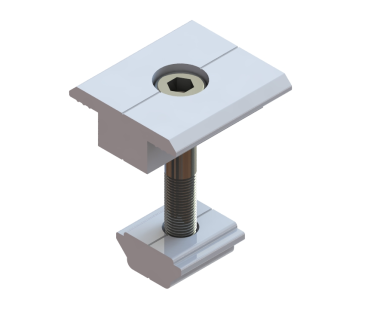

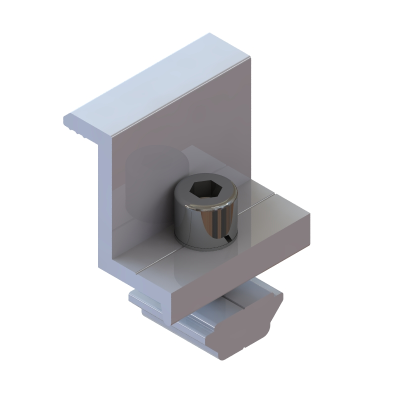

Solar mounting modules common frame accessories include bracket, solar clamp, hook, grounding wire...., etc.

The solar components has aluminum alloy material, also has stainless steel material, as well as some zinc ferroalloy and so on.General double glass components with the pressing block will have a rubber pad inside the metal clamp, usually using hard EPDM rubber, and corrugated groove to increase the contact area with the glass, increase friction.Rubber pads are also available for stainless steel or zinc-ferroalloy presses to avoid scratching the assembly border

PV modules shall be tested in accordance with IEC 61215, 61730 and other standards for power generation performance, physical and mechanical performance, safety performance and weather resistance.Various accessories directly installed on the frame form a whole with photovoltaic modules. Although similar tests for "module + accessories" have not been required, it is still necessary to consider whether these accessories will affect the power generation, strength, safety, weather resistance and other performance of the module.

PV modules need to be tested for insulation performance, ground continuity test, PID resistance performance test, flame retardant grade test, humidity and heat aging test, etc.

Kinsend's photovoltaic modules are fully immersed in all parts on the surface galvanized surface, and then perfectly protected from the lack of corrosion protection on the cross-section.Provide customers with a 10 - year warranty for the bracket.Please send an email to Info@kinsend.com or follow our enterprise platform to learn more about our products.

Hot Sale Solar Mounting Solutions recommend for you